Amidst growing global demands for sustainable manufacturing, the Fraunhofe ...

WE CAN SEE THE FUTURE OF

mold manufacturing

We are pioneering a flexible manufacturing approach for recyclable bio-based high-performance composite molds.

New innovative molds promise to reduce production-related CO2 emissions and cost contribution to less than 5 % compared to the current 25 %.

The Future Mold project can help significantly reduce the carbon footprint and production costs of machinery industries that use lightweight fiber-reinforced plastic (FRP) components, such as rail, marine, aerospace, and agricultural.

The novel approach results in significant advantages over classical methods for mold production.

The new generation of innovative molds has these key benefits.

KEY BENEFITS

ECO-FRIENDLY

Reduces mold production’s contribution to CO2 emissions to less than 5 %.

ADVANCED TECHNOLOGY

Combines 3D printing and Incremental Sheet Metal Forming (ISF) for superior mold durability and performance.

COST-EFFICIENT

Mold manufacturing costs are cut by 30 %, and material usage is reduced by 80 %.

SUSTAINABLE MATERIALS

Reduces reliance on steel and glass fiber by using bio-based, recyclable composites.

LONGEVITY

The new approach extends mold service life by 300 %, improving production quality and efficiency over time.

DIFFERENCE IS MAJOR

NOWADAYS MOLDS

Currently, molds produce plastic and composite parts in small batches, which requires a high level of manufacturing effort.

These molds are either milled from energy- and waste-intensive solid steel blocks or manufactured using a lost mold in an elaborate hand-laminate process.

In particular, glass-reinforced plastic (GRP) molds require heavy maintenance and wear out quickly after a certain number of molded parts.

This creates a large volume of disposable material since molds are not reusable nowadays.

As a result, the mold design largely determines the carbon footprint and costs of the manufactured parts, up to 25 %, depending on volume.

FUTURE MOLDS

Using a next-generation recyclable composite mold will reduce the amount of mold needed in a production process.

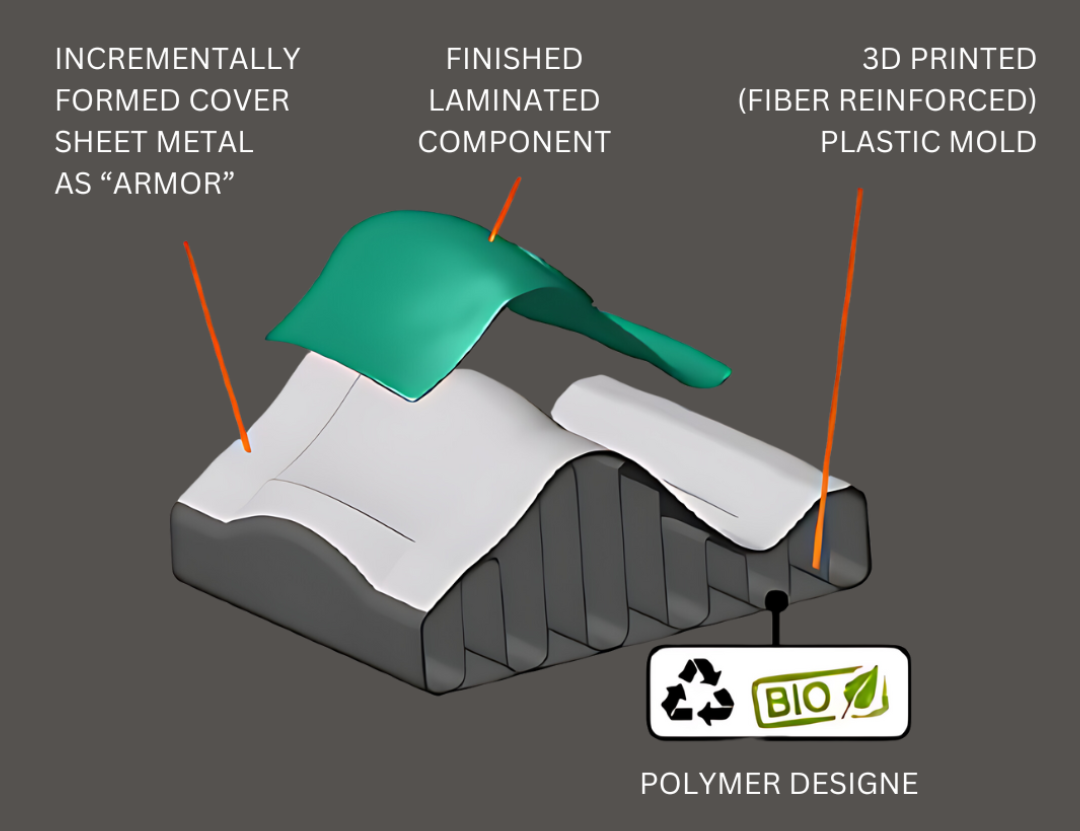

The concept is anticipated to consist of two parts that will be incorporated into a hybrid mold.

The 3D-printed base body is made from fiber-reinforced biopolymer and covered by a molding surface, an incrementally formed sheet metal.

The detachable connection of the metal cover layer to the mold base body ensures complete mold recycling.

Mold production in the CO2 emission and the costs of the composite component will be reduced to less than 5%.

The FutureMold solution

A game changer for the machinery industry.

Imagine the impact if production-related CO2 emissions and cost contribution were reduced by 20 % in all industries below.

The project is expected to set new standards in the production of FRP molds and contribute to a more sustainable manufacturing process across multiple industries. Through collaboration and cutting-edge technology, FutureMold will lead to significant advancements in producing lightweight and high-performance components.

RAIL

aerospace

marine

agriculture

ABOUT THE PROJECT

AND CONSORTIUM

The Future Mold project is supported by the open call of EU-funded network M-ERA.NET, which was established to support and enhance the coordination of European research programs and related funding in the field of materials science and engineering, specifically for research and innovation on materials and battery technologies, supporting the European Green Deal.

The FutureMold project is run by a collaborating consortium of international partners from the Czech Republic, Poland, and Germany, namely:

- F-IWU (Coordinator) brings expertise in ISF (Incremental Sheet Metal Forming), 3D printing, and FRP technologies, focusing on the development and validation of molding tools.

- IT4Innovations & VSB-TUO contributes its skills in process digitization, developing virtual twins and surrogate models, and conducting necessary numerical simulations.

- SVS FEM applies its extensive experience in numerical simulations to optimize the ISF process.

- AMU has specific expertise in organosilicon chemistry, including the synthesis and application of silanes and (poly)siloxanes, including silane coupling agents, adhesion promoters and filler surface treatment.

- STER serves as a supplier for public transport, aiding in material development and technology evaluation.

This partnership leverages each member's unique strengths to achieve the project’s ambitious goals.

Do you want to know more?

CONTACT THE PROJECT COORDINATOR